ASH WIN ENGINEERS, having made its modest beginning in 1992 at Ahmedabad, India. Which is now undisputed player in manufacturing and export of State of the art full range of Rotomolding machines, Microfine Pulvering system, Compounding Extrusion Lines, Highspeed Mixers, Scrap Granulators, Vibratory Screens, Rotational Moulds of Mild steel/ Stainless steel and also other related Plastics auxiliary equipments. The promoters are visionary engineers who are possessing strong technical as well as management back ground with focus in manufacturing of Plastic Rotational Molding Plants and Extrusion processing plants.

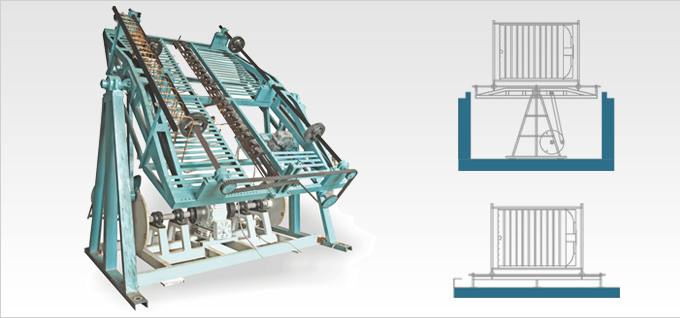

Rock N Roll Machine

"Total Commitment to Customer Satisfaction"

Rock N Roll Rotomolding Machines

Optional : Crane, Cooling Station, Chain Pulley Block Polishing Grinder.

Salient Features:

Technical Specification

| Particular | Unit | Models |

| - | - | AER-2000 | AER-5000 | AER-10000 | AER-25000 | AER-35000 | AER-50000 |

| Suitable container range | Ltr | 200-2000 | 200-5000 | 200-10,000 | 500-25000 | 500-35000 | 500-50000 |

| Frame size : L x W | Mtr | 3 x 2 | 3.5 x 2.2 | 5 x 3 | 6 x 4 | 6.5 x 4 | 7.5 x 5 |

| Pit size: L x W xD | Mtr | 4x 2.5 x 2 | 4.5 x 3 x 2.2 | 6 x 3.5 x 2.8 | 7 x 4.5 x 3 | 7 x 4.5 x 3.5 | 8.5 x 5.5 4.5 |

| Type of Fuel | - | Diesel/Gas | Diesel/Gas | Diesel/Gas | Diesel/Gas | Diesel/Gas | Diesel/Gas |

| Total connected load | HP | HP | 7.5 | 16 | 27 | 39 | 56.5 |

Advantages Of Rotational Molding