ASH WIN ENGINEERS, having made its modest beginning in 1992 at Ahmedabad, India. Which is now undisputed player in manufacturing and export of State of the art full range of Rotomolding machines, Microfine Pulvering system, Compounding Extrusion Lines, Highspeed Mixers, Scrap Granulators, Vibratory Screens, Rotational Moulds of Mild steel/ Stainless steel and also other related Plastics auxiliary equipments. The promoters are visionary engineers who are possessing strong technical as well as management back ground with focus in manufacturing of Plastic Rotational Molding Plants and Extrusion processing plants.

Extruder

"Total Commitment to Customer Satisfaction"

Extrusion Lines For Colouring, Reprocessing Granules.

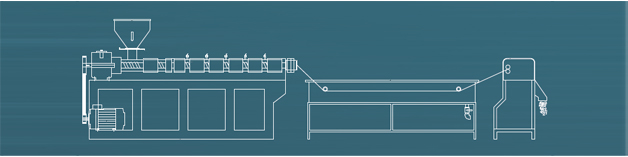

Layout Diagram:

Optional Features : Vacuum Hopper Loader, Die face cutter, Chiller, PLC, Synchronization circuit

General Description

The LLDPE raw material with suitable master batch is being fed in to the barrel cylinder through storage hopper. The barrel is preheated by heating zones and suitable temperature control system to process the input material. The rotating screw pushes the material towards die end with uniform and homogenized plastics melt. The screw is rotated by suitable AC motor coupled with heavy duty gearbox. The plastics strands extruded from die are fed in to high speed Pelletiser unit after they get cooled and traveled through SS water cooling tank. Pelletiser cuts the strands in to desired size of pellets which can be collected in to storage silo.

Salient Features

Technical Specification

| Particular | Unit | Models |

| - | - | AEX-75 | AEX-90 | AEX-100 | AEX-110 |

| Main Motor | kw | 18.25 | 22.25 | 37.25 | 45.00 |

| Output in LLDPE | Kgs/hr | 120 | 150 | 200 | 250 |

| Floor space Required, | Mtr | 7.5x 2.0x 2.0 | 9.0x3x2.2 | 9.5x3x2.2 | 9.5x3x 2.2 |

Advantages Of Rotational Molding

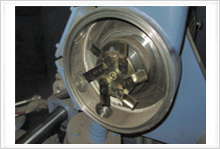

Die Face Cutter

Die Face Cutter Screw

Screw  Strand Die

Strand Die